Introduction

It was my diploma project. I decided to build a spin-coater because of few reasons. Firstly because it required innovative and creative thinking skills. Second reason was the manual work: I had to not only design but also build machine that would work. That wasn’t an easy task…

The goal was to use recycled materials/parts and build spin-coater: machine to produce thin polimer layers. Using recycled materials had two main reasons. First – price: spin coater can cost few tousand bucks (check google!). Second – environment: it was good (for mother earth) fun (for me) to build something out of trash. I used about 70% recycled mechanical/electronic parts in this project.

What is spin-coater?

Well, in a nutshell it is machine that uses centrifugal force to produce thin layers,

in example thin polymer films. What for? In past decades there was a rapid growth of

polymers usage. Many new technologies are based on polymer, because it conducts

current, it is plastic, corrosion proof and relatively cheap.

You can find

thin polymer layers in light sensors, thermometers (and other medical equipment),

millitary technologies (anti-radar paints) and many others.

Just a bit of theory

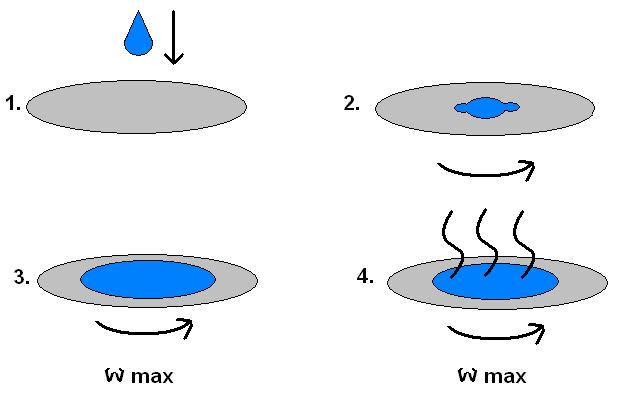

In theory, spin coating process is very simple. As you probably can guess, it has

something in common with spinning around and covering something. That’s true.

Spin coater uses centrifugal force, surface tension and evaporation of the liquid

polymer solution to get on a spinning disc very thin films (few micrometers) of the

polymer. Firstly, you need to put one drop of polymer on static disc. Next, you need

to speed up the disc to some high rotational speed (let’s say the higher speed

– the thinner layer). Then, at a high, permanent speed, solvent from solution

must evaporate. As a final efect you will get thin polymer film. By controlling

rotational speed you can also controll thinness of the layer.

In practice it

is not so simple. Thinness also depends on many factors: time of the spinning, the

way how you put polymer on disc, smoothness of the disc and many others. Let’s

check how the process looks like:

1. Polymer deposition on the disc

It is the first sequence of the

process, it provides liquid polymer on disc surface. I used a syringe as a

dispenser. For higher precission, it was controlled by stepper motor.

2. Speed-up

Second sequence of the process, in which liquid polymer

spreads around the disc because of the disc rotation (and centrifugal force). After

that, disc speeds-up to almost maximum rotational speed so that expected thinness is

almost final. In this sequence speed is about 1500 to 3000 rpm’s. It can take

few second or few minutes, depending on what polymer we use.

3. Making layer more flat

In third sequence thinness gets its maximum

value. The surplus of the liquid is thrown away from disk by centrifugal force.

4. Evaporation

Last sequence of the process. Liquid polymer is

coagulating, when solvent evaporates.

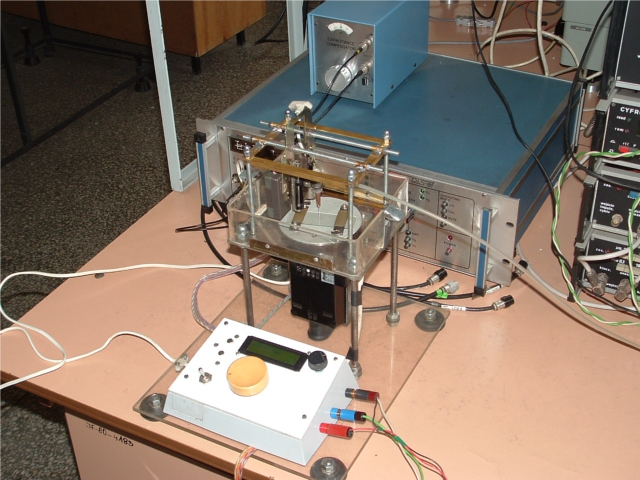

Designing and making spin-coater

Disc driver

I started work on machine from choosing proper electric

motor to speed up the disc. Because of costs I decided to use commutator motor with

permanent magnet (from old sewing machine). It has 90 W of power with 4500

rpm’s. Good enough. Of course better option would be small, brushless motor

from HDD (7k rpm’s) but controll process of such device was too complicated

for this project. I controlled the speed of commutator motor by dedicated module

based on triac.

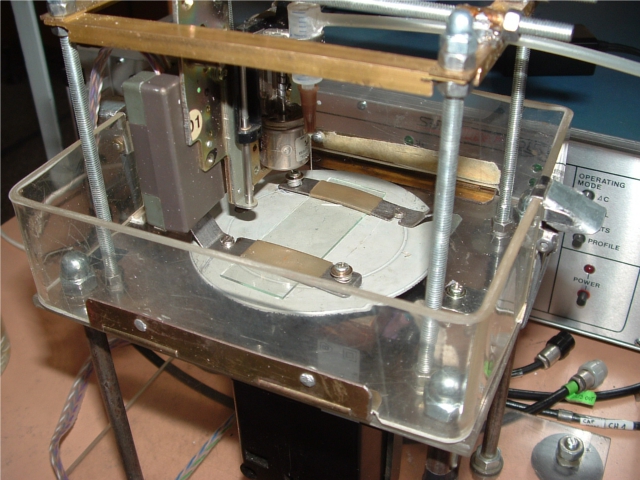

Stepper motor

Second motor that I used in project was a stepper motor

from old FDD drive (5,25″). It was responsible for precise movements of

dispenser with liquid polymer.

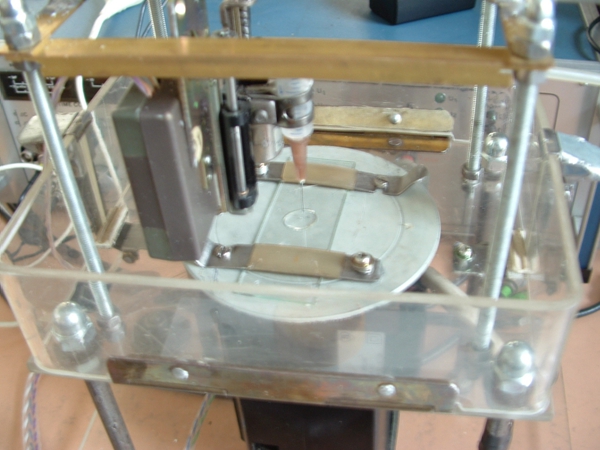

Liquid polymer dispenser

Next stage of the design was to create

something that would put drop of polymer on the disc. Because stepper motor

wouldn’t move some heavy device, I implemented medical syringe with needle for

that.

Disc and sample glass fixing system

I had a little trouble fixing the

glass sample to disc. It would had to be strong enough to keep sample on disc when

it speeds up to few k rpm’s, and gentle enough to not break the glass.

Moreover fixing system had to be easy enough to put/take sample to/from disc. I used

two metal plates as a fixing system. I was forced to put plexiglass shields around

the disc, just in case metal plates would be dropped at higher speed.

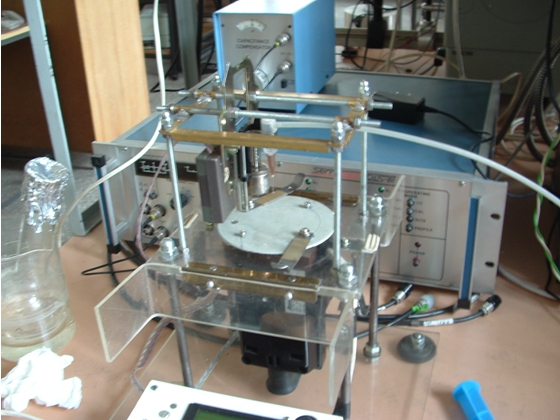

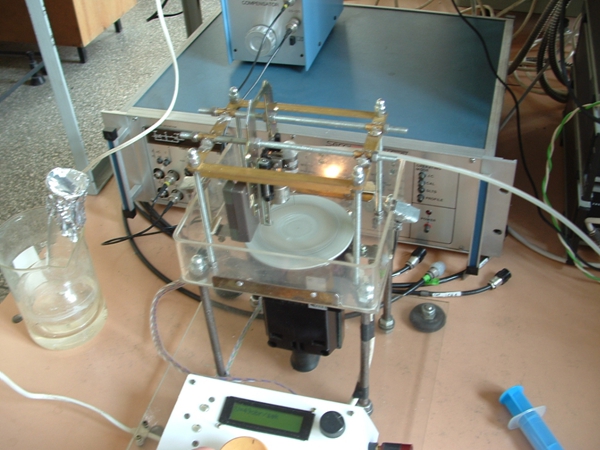

Frame construction

I build frame for my machine using plexiglass (light

and easy to form after heating) and cooper (easy to solder). That is why

construction was light and heavy-duty. Because of motor, whole machine got much

vibrations. I reduced them adding rubber silent-blocks under frame construction.

Desktop

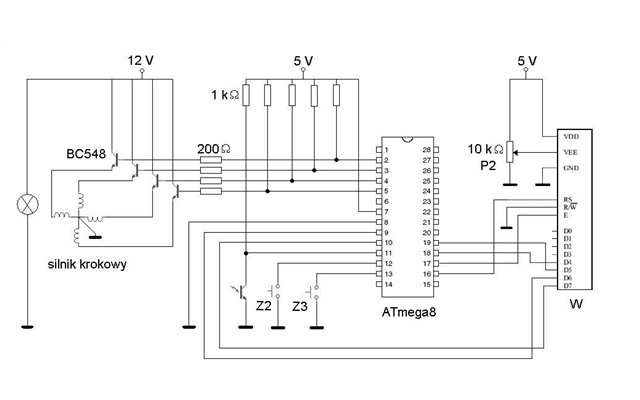

Logic of the system was based on ATmega8 microcontroller. It

managed LCD display (HD44780 Hitachi) and stepper motor.

LCD and potentiometers (one for controlling brightness of LCD, second for controlling speed of the disc) was placed on desktop. Having all buttons on white piece of plastic was a good choice. My machine got a little bit of design beauty:)

Tachometer

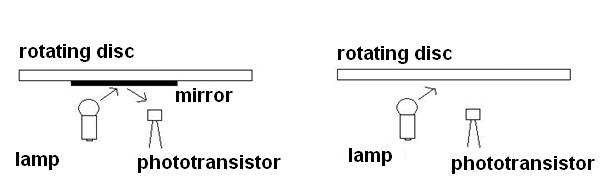

Spin coating process depends on rotational speed, so I needed

to check how fast disc is rotating at the moment. I implemented simple mechanism

with mirror, phototransistor and light bulb. I put small mirror under the disc. At

the time when light from bulb reaches the mirror, phototransistor conducts current.

In this way microprocessor caunted electrical impulses per minutes – which are

of course rounds per minutes. Final value of the speed was visible on LCD display

(displayed with 3 s frequency).

Summary

I had a great time working on spin-coater. I’ve compleated it in 2006. By that time, it was my first bigger experience with microcontrollers. There are some things I could’ve done better, but spin-coater worked and that was most important in the project!